- Home

- Products

T-Slot Aluminium Range

Work Area Solutions

Conveyors & Components

- Services

- Why Siyamuva

- Contact Us

Slide

AmbaFlex SpiralVeyor, AmbaVeyor and AccuVeyor

The AmbaFlex conveyor range is endlessly flexible.

The AmbaVeyor system can be easily manipulated to suit almost all conveying requirements, especially over long lengths or where there are multiple orientation chances, such as turns, inclines or declines. Due to the engineering behind AmbaVeyor, track lengths of up to 50m can be managed with one geared drive, ensuring reduced energy consumption. With simplified software and control systems, and – most importantly – reduced maintenance and spares requirements, the AmbaVeyor significantly minimises the cost of ownership. The AmbaVeyor offers a range of solutions for product handling applications and for most packaging applications.

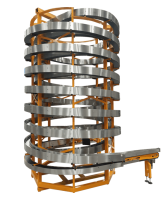

Using the same engineering philosophy employed in the AmbaVeyor, the SpiralVeyor range includes all the benefits of the AmbaVeyor, but with increased space savings. With the SpiralVeyor, you can elevate or lower products to multiple floor levels within a footprint as small as 2m2, saving you one of the most expensive commodities in any production or warehouse environment – floorspace.

AmbaFlex SpiralVeyor range

AmbaFlex’s SpiralVeyor range is designed to move products up or down, with applications ranging from handling parcels or totes in logistical processes, to primary and secondary packed consumer items, all the way through to print finishing.

SpiralVeyor – SV series

For cartons, packs and cases

The SpiralVeyor SV is the all-purpose spiral conveyor for medium to large products. It is ideal for handling secondary packed products and cases in logistics, and can be utilised for multiple functions ranging from elevation to accumulation.

The lateral roller system is simple and reliable, rendering controls and sensors superfluous. The continuous motion provides the perfect solution for the exacting situations involving unstable products and high production speeds. Having been installed in thousands of factories and workshops worldwide, including demanding multinational clients, the SpiralVeyor SV sets the standard for the industry.

The SpiralVeyor SV is suitable for:

- Cartons

- Containers

- Trays

- Bottle packs

- Bags

- Crates

- Totes

Technical details:

- Belt width range: 300-600mm

- Multi-belt: 1-3 parallel belts

- Load range: Up to 50kg/m per belt

- Speed range: Up to 60m/minute

- Elevation: Virtually unlimited, but generally 15m per drive system

- Belt length: Up to 60m per drive system

SpiralVeyor SVo series

For totes and crates

The SpiralVeyor SVo series is AmbaFlex’s economic solution for handling cases with repeating sizes. It is specifically designed to handle rigid items with the same farm factor, and is based on single-track technology.

The difference is in the belt design, with a scorpion back style and shape. This design ensures a line contact with much more grip on the items being handled, allowing the machine to stably elevate items that are larger than the belt width, and at higher inclines, for a smaller financial investment.

The SpiralVeyor SVo is suitable for:

- Totes

- Plastic containers

Technical details:

- Chain width range: 100mm

- Nominal clear product width: 300mm, 400mm, 600mm

- Load range: Up to 35kg/m

- Speed range: Up to 60m/minute

- Elevation: Virtually unlimited, but generally 15m per drive system

- Belt length: Up to 60m per drive system

SpiralVeyor SVe series

For large items and parcels

The SpiralVeyor SVe series is AmbaFlex’s extreme wide-belt spiral conveyor, specifically designed to handle oversized products, parcels and bulk flow.

The SVe has a design that is up to 50% more compact, and a belt that is 30% wider than other spiral conveyors on the market today – for large items and parcels, there is no comparison. The wide belt is created by multiple parallel tracks that form one conveyor belt. This arrangement ensures enhanced pull strength for high load applications, all while remaining the most compact spiral conveyor available.

The SpiralVeyor SVe is suitable for:

- Cartons

- Parcels

- Luggage

- Crates

Technical details:

- Belt width range: 600-1200mm

- Multi-track belt: 2 or 3 parallel belts

- Load range: Up to 100kg/m total per belt

- Speed range: Up to 60m/minute

- Elevation: Virtually unlimited, but generally 15m per drive system

- Belt length: Up to 60m per drive system

AmbaFlex AmbaVeyor

Easily convey items from A to B with minimum transfers using the AmbaFlex AmbaVeyor. This unique side-flexing conveyor solution is based on proven SpiralVeyor belt technology, and boasts a low investment due to its simplicity, long runs and integrated curves and inclines.

AmbaVeyor

Endless flexibility

The AmbaVeyor conveys items from A to B with the minimum of transfers and drives, and is a modular conveyor system designed for the internal transport of unit loads. The main elements of the AmbaVeyor are the frame and the belt. The belt’s unique ability to flex sideways and to go through upward and downward bends allows the AmbaVeyor to incorporate straight, inclined and curved tracks in a one-drive conveyor system that can extend over distances of up to 50 metres.

The AmbaVeyor is suitable for various types of goods, depending on the application.

Technical details:

- One continuous conveyor solution incorporating straights, inclines and curves

- High load capacity: Up to 50kg/m

- Unique modular conveyor system

- 24-hour stock supply

AmbaVeyor predefined curved solutions

9 predefined curved solutions that fit almost every job

The AmbaVeyor is a flexible conveyor system that can run over long distances and include curves, straights and inclines with a single belt. However, there is a demand for smaller, ready-to-run, pre-assembled curved solutions that can be integrated into traditional conveyor lines in order to resolve complex conveying issues.

As an all-in-one conveyor solution, the AmbaVeyor allows you to reduce your investment in conveying.

Above and beyond the AmbaVeyor features and benefits, AmbaFlex has a range of curved solutions that can enhance a complete line by cutting drives and transfers, and reducing the space needed – even on shorter conveyor tracks. These pre-assembled and tested modules can be fitted in most challenging areas as a quick and effective fix.

AmbaFlex AccuVeyor

The AccuVeyor is an accumulator that allows you to accumulate products both on- and offline. AmbaFlex has accumulation solutions for all kinds of products and industries, allowing you to increase efficiency by balancing speed differences in a production line, processing products by time delay, or buffering items offline in an intermittent process.

AccuVeyor AVh series

Dynamic accumulation for primary packaging

The AccuVeyor AVh has been designed to overcome the disadvantages of traditional spiral accumulators.

This module does not touch the products in any way. Better yet, the products do not even change tracks, but remain on the same portion of conveyor belt, in-between the infeed and outfeed parts. This means that, rather than the products changing direction, it is the conveyor belt itself that makes this change. The unique, no-compromise, patented system was designed by combining AmbaFlex’s experience with spiral conveyors with their knowledge of dynamic accumulation.

The AccuVeyor AVh is suitable for:

- Primary packing, such as cartons, candy bars, biscuit packs, personal care and pharmaceuticals

- Filled liquid containers, such as pouches, doypacks, bottles and cans

- Delicate packs

- Multiple products being transported in parallel

Technical details:

- Belt width range: 140mm

- Multi-belts: Patented one-belt non-touching accumulation system

- Load range: Up to 15kg/m

- Speed range: Up to 40m/minute

- Accumulation length: Up to 80m

AccuVeyor AVL series

Dynamic buffer for primary packaging

The AccuVeyor AVL is a fully-dynamic accumulator suited for various applications. The dynamic effect allows for the absorption and release of items between processes without any interruption.

This module is based around one flexible conveyor belt. This belt consists of two U-shaped conveyor segments on the top and two return belt segments underneath, running through a conveyor frame. The top U-shape is the effective accumulator, conveying products from the entrance to the exit. The bottom U-shape is used to store any unused conveyor belt. When accumulating, the U-shaped segment moves along the track, thereby increasing or reducing the accumulation length – just like a trombone.

The AccuVeyor AVL is suitable for:

- Small cartons

- Pouches

- Sealed cups

- Flow packs

- Cups

- Jars

- Trays

Technical details:

- Belt width range: 140mm, 400mm, 600mm

- Multi-belts: Patented one-belt non-touching accumulation system

- Load range: Up to 15kg/m

- Speed range: Up to 42m/minute

- Accumulation length: 40m

AccuVeyor AVs series

Time delay

The AccuVeyor AVs series provides time delay or medium pressure accumulation, and has been specifically designed to save space.

The module’s ultra-compact design offers an astonishing 51m/m2 (15.5ft/ft2) conveyor metres per square metre footprint. Based on a SpiralVeyor SVs, the AccuVeyor AVs has one belt that runs both up and down in a concentric arrangement. When installed in its time delay configuration, the AVs offers the most time delay in the least space possible. In this configuration, it is compact and simple, able to handle almost all primary packed products as well as liquid containers in single file. When used as a medium pressure accumulator, the smooth belt surface slips under the items.

The AccuVeyor is suitable for:

- Liquid containers, such as bottles, glass or PET for drinks, personal care and pharmaceutical

- Primary packing, such as cartons, candy bars, personal care and pharmaceuticals

Technical details:

- Belt width range: 100-140mm

- Multi-belts: Patented up/down spiral with one belt

- Load range: Up to 50kg/m

- Speed range: Up to 60m/minute

- Belt length: Generally 120m per drive system